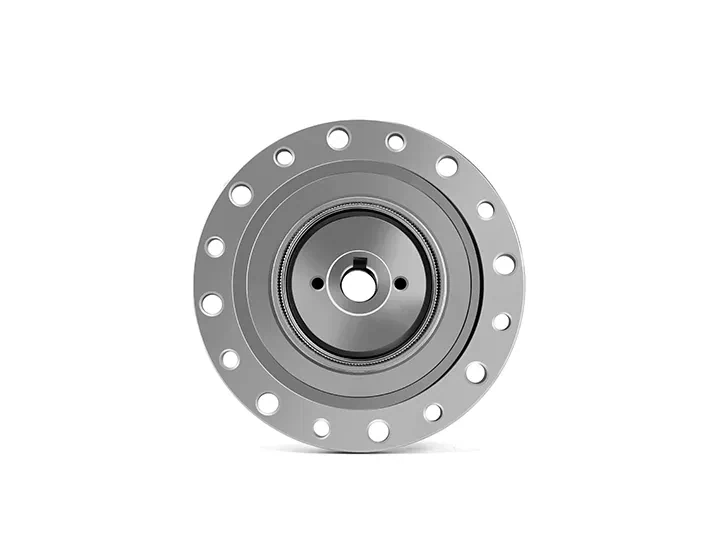

SSG High Torque Harmonic Drive

This harmonic reducer features a cup-shaped flexible wheel that adheres to standard barrel design principles, which is specifically tailored for applications requiring substantial torque. It offers a torque-bearing capacity that exceeds the High Precision Harmonic Gearbox series by more than 30%, and it also delivers an impressive increase in lifespan, exceeding 43%, all while aiming for optimal load-bearing capability and dependability.

PRODUCT FEATURES

This harmonic reducer boasts a compact, cup-shaped design that is both simple and efficient. It eliminates backlash for smooth, precise movement, with input and output shafts perfectly aligned. Its exceptional positioning and rotational accuracy make it ideal for high-precision applications.

PRODUCT ADVANTAGES

- The flexible wheel is housed in a cup-shaped barrel structure that is standard and offers high rigidity, complemented by robust full roller cross bearings.

- This tooth profile is designed with a proprietary CMP heat treatment process, ensuring precision grinding with an accuracy of 1 micrometer.

- The design is streamlined and compact, ensuring no play or slack in the system, allowing for a direct connection to the motor and straightforward installation.

- The input and output are aligned on the same axis.

- The input and output shafts are aligned coaxially.

- It provides superior accuracy in positioning and consistent repeatability.

PRODUCT DESCRIPTION

This harmonic reduction gear matches the High Precision Harmonic speed reducers in size but features a flex spline with enhanced hardness due to a different heat treatment process. By increasing the gear contact area, we’ve achieved a 30% boost in torque capacity, which also extends the SSG series’ service life by 43%.

SPECIFICATIONS

Specification of High Torque Harmonic Drive Rated Parameters

| Model | Reduction ratio | Rated torque at 2000r/min input | Permissible peak torque at start and stop | Permissible maximum value for average load torque | Permissible maximum momentary torque | Permissible maximum input rotational speed | Permissible average input rotational speed | Backlash | Weight | Design life | ||||

| Grease | Grease | |||||||||||||

| Nm | kgfm | Nm | kgfm | Nm | kgfm | Nm | kgfm | r/min | r/min | Arc Sec | kg | Hour | ||

| 14 | 50 | 7 | 0.7 | 23 | 2.3 | 9 | 0.9 | 46 | 4.7 | 8500 | 3500 | ≤20 | LSG-I/II:0.51 | 10000 |

| 80 | 10 | 1 | 30 | 3.1 | 14 | 1.4 | 58[1] | 5.9[1] | 15000 | |||||

| 100 | 10 | 1 | 36 | 3.7 | 14 | 1.4 | 58[1] | 5.9[1] | 15000 | |||||

| 120 | 10 | 1 | 36 | 3.7 | 14 | 1.4 | 58[1] | 5.9[1] | 15000 | |||||

| 17 | 50 | 21 | 2.1 | 44 | 4.5 | 34 | 3.4 | 91 | 9 | 7300 | 3500 | ≤20 | LSG-I/II:0.67 | 10000 |

| 80 | 29 | 2.9 | 56 | 5.7 | 35 | 3.6 | 109[1] | 11[1] | 15000 | |||||

| 100 | 31 | 3.2 | 70 | 7.2 | 51 | 5.2 | 109[1] | 11[1] | 15000 | |||||

| 120 | 31 | 3.2 | 70 | 7.2 | 51 | 5.2 | 109[1] | 11[1] | 15000 | |||||

| 20 | 50 | 33 | 3.3 | 73 | 7.4 | 44 | 4.5 | 127 | 13 | 6500 | 3500 | ≤20 | LSG-I/II:0.96 | 10000 |

| 80 | 44 | 4.5 | 96 | 9.8 | 61 | 6.2 | 165 | 17 | 15000 | |||||

| 100 | 52 | 5.3 | 107 | 10.9 | 64 | 6.5 | 191 | 20 | 15000 | |||||

| 120 | 52 | 5.3 | 113 | 11.5 | 64 | 6.5 | 191 | 20 | 15000 | |||||

| 160 | 52 | 5.3 | 120 | 12.2 | 64 | 6.5 | 191 | 20 | 15000 | |||||

| 25 | 50 | 51 | 5.2 | 127 | 13 | 72 | 7.3 | 242 | 25 | 5600 | 3500 | ≤20 | LSG-I/II:1.46 | 10000 |

| 80 | 82 | 8.4 | 178 | 18 | 113 | 12 | 332 | 34 | 15000 | |||||

| 100 | 87 | 8.9 | 204 | 21 | 140 | 14 | 369 | 38 | 15000 | |||||

| 120 | 87 | 8.9 | 217 | 22 | 140 | 14 | 395 | 40 | 15000 | |||||

| 32 | 50 | 99 | 10 | 281 | 29 | 140 | 14 | 497 | 51 | 4800 | 3500 | ≤20 | LSG-I/II:3.11 | 10000 |

| 80 | 153 | 16 | 395 | 40 | 217 | 22 | 738 | 75 | 15000 | |||||

| 100 | 178 | 18 | 433 | 44 | 281 | 29 | 841 | 86 | 15000 | |||||

| 120 | 178 | 18 | 459 | 47 | 281 | 29 | 892 | 91 | 15000 | |||||

| 40 | 50 | 178 | 18 | 523 | 53 | 255 | 26 | 892 | 91 | 4000 | 3000 | ≤20 | LSG-I/II:4.6 | 10000 |

| 80 | 268 | 27 | 675 | 69 | 369 | 38 | 1270 | 130 | 15000 | |||||

| 100 | 345 | 35 | 738 | 75 | 484 | 49 | 1400 | 143 | 15000 | |||||

| 120 | 382 | 39 | 802 | 82 | 586 | 60 | 1510[1] | 154[1] | 15000 | |||||