Harmonic Drive

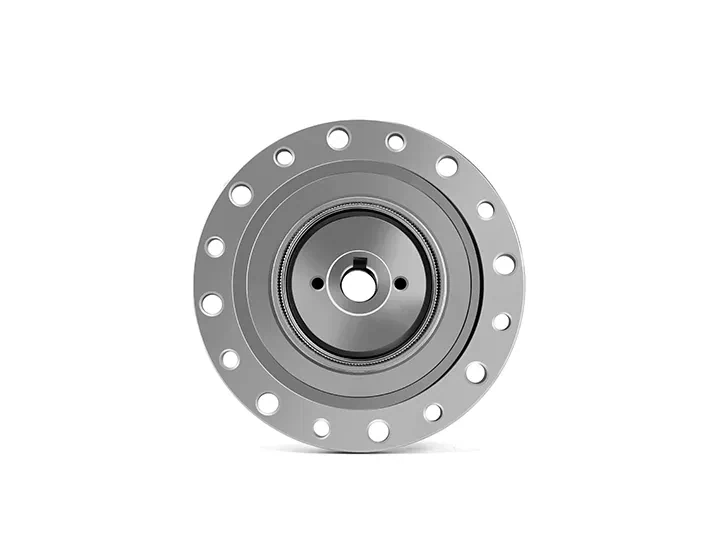

The harmonic drive, often referred to as a harmonic gearbox or reducer, is composed of three primary components: the wave generator, the flexible spline, and the circular spline. Our product offers several advantages, including the elimination of backlash, minimal heat generation, low starting torque, high dependability, substantial load-bearing capability, extended service life, significant speed reduction ratios, compact dimensions, and more. Seninter drive stands as a leading producer in this field, boasting over a decade of expertise in research and development.

Harmonic Drive Industry Knowledge

A harmonic drive gearbox is a precision gear assembly designed for compact dimensions, capable of generating substantial reduction ratios. It operates by the deformation of a flexible component to transfer motion, thereby ensuring high accuracy and torque output.

A harmonic drive gearbox operates through the interaction of a circular rack, a flexible spline, and a wave generator. The wave generator induces an elliptical distortion in the flexible spline, causing it to mesh with the circular rack at two distinct locations. This engagement leverages the disparity in the number of teeth between the two components to achieve a significant gear reduction.

The key parts consist of the circular spline (stationary outer ring), the flexspline (pliant inner ring with a lesser number of teeth), and the wave generator (an oval-shaped disc that is housed within the flexspline).

Strain wave or harmonic drive systems provide exceptional accuracy, eliminate back-slack, deliver substantial torque, and are characterized by their compactness and reduced weight. They are recognized for their superior accuracy in maintaining position and their consistent reliability in reproducing movements.

They find utility in scenarios that demand exactitude and dependability, encompassing fields like robotics and automation, aerospace, machinery, medical devices, semiconductor machinery, communication apparatus, and logistics.

The choice hinges on considerations such as the necessary torque, the reduction ratio sought, spatial limitations, the load that needs to be handled, and the conditions of the environment. Engaging with manufacturers or specialists for guidance on selecting the right strain wave drive model is crucial.

Cup-type Gearboxes

Hat-type Gearboxes